News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

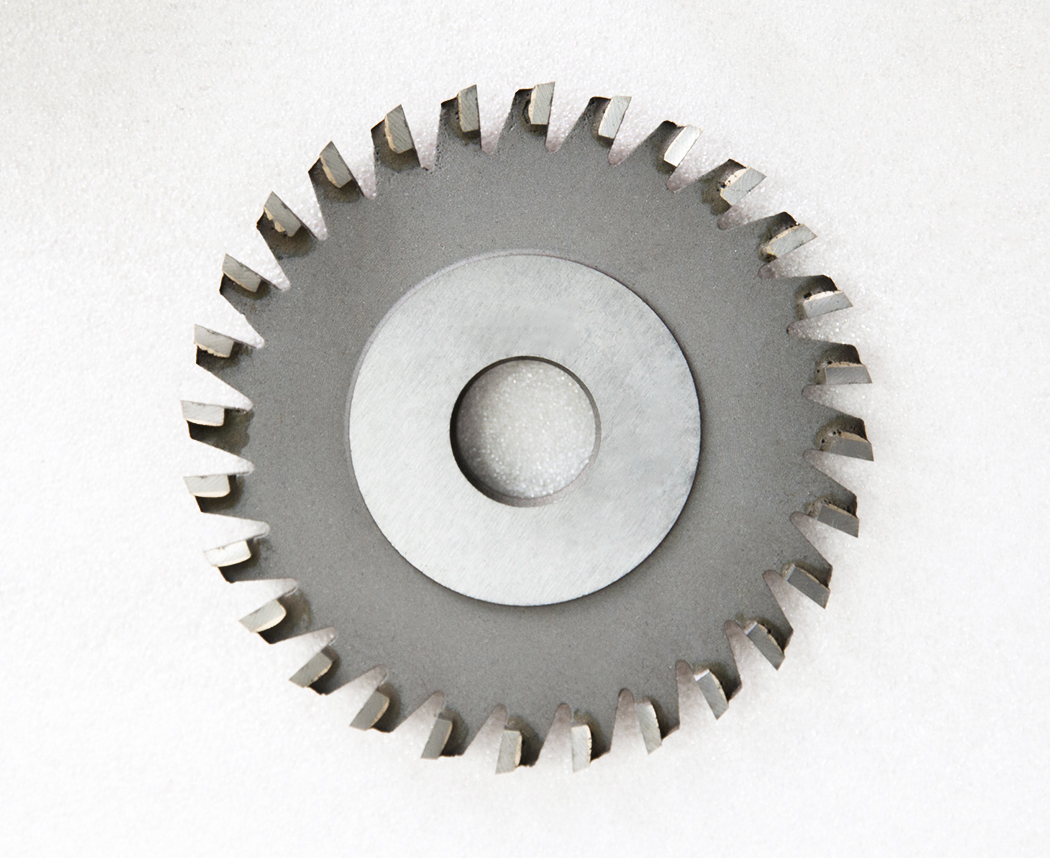

What are the advantages of tooth face milling cutter

The three sided milling cutter with embedded teeth mainly has the following advantages:Sources:www.fhc018.com | PublishDate:2025.01.14

1、 Good durability of cutting tools

1. Easy replacement of cutting edges

The cutting edge of a three sided milling cutter with embedded teeth is composed of multiple embedded teeth. When a damaged tooth is worn or chipped, it is only necessary to replace the damaged tooth instead of scrapping the entire tool like a solid tool. This reduces the cost of tool usage and also reduces production downtime caused by frequent tool replacement. For example, in batch milling, if a solid three sided milling cutter is used, once the cutting edge of the tool is damaged, a new tool needs to be replaced and the tool parameters need to be readjusted, which will consume a lot of time; By using a three sided milling cutter with embedded teeth, it is possible to quickly replace the embedded teeth and continue machining.

2. Improve the utilization rate of tool materials

The toothed tool can be made of high-performance tool materials for the toothed part, while the blade body can be made of relatively low-cost materials. Due to the high cost of high-performance tool materials, this structural design allows for more rational use of materials while ensuring cutting performance, reducing the overall cost of the tool. For example, hard alloy can be used for the tooth setting part, which has high hardness and good wear resistance, but also high cost; The blade body is made of ordinary alloy steel, which has a lower cost and achieves optimized material combination while meeting cutting requirements.

2、 Excellent cutting performance

1. Adapt to multiple cutting parameters

The three sided milling cutter with embedded teeth can withstand large cutting forces, so higher cutting speeds, feed rates, and cutting depths can be used. Under appropriate machining conditions, higher cutting parameters mean higher machining efficiency. For example, when milling alloy steel materials with high hardness, a three sided milling cutter with embedded teeth can effectively perform cutting by adjusting the cutting parameters reasonably, without the phenomenon of rapid edge wear or chipping like some ordinary cutting tools.

2. High cutting edge accuracy

During the manufacturing process, tooth inserts can be precisely machined and inspected to ensure the geometric shape and dimensional accuracy of each tooth insert. After assembly onto the tool body, high-precision cutting edges can be formed, resulting in good surface quality and high dimensional accuracy of the machined workpiece. For example, when milling flat surfaces, lower surface roughness can be obtained, and when milling grooves with dimensional accuracy requirements, the width, depth, and other dimensional accuracy of the grooves can be ensured to meet the machining requirements.

3、 Strong universality of cutting tools

1. Multiple tooth shapes to choose from

The three sided milling cutter with embedded teeth can choose different tooth profiles according to different machining needs. Common tooth shapes include straight teeth, staggered teeth, and helical teeth. Straight teeth are suitable for general milling operations; Interlocking teeth can reduce the fluctuation of cutting force and are suitable for processing tough materials; Spiral teeth are beneficial for chip removal and perform well in deep groove milling or processing viscous materials. Such multiple tooth profile options enable the tool to adapt to various workpiece materials and machining conditions.

2. Can combine different tooth setting materials

According to the characteristics of the processing materials, different materials can be combined for tooth inlay. For example, when processing composite workpieces with both soft and hard materials, high-speed steel teeth suitable for cutting soft materials and hard alloy teeth suitable for cutting hard materials can be installed on a milling cutter, thereby achieving efficient processing of composite workpieces through one tool.