News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

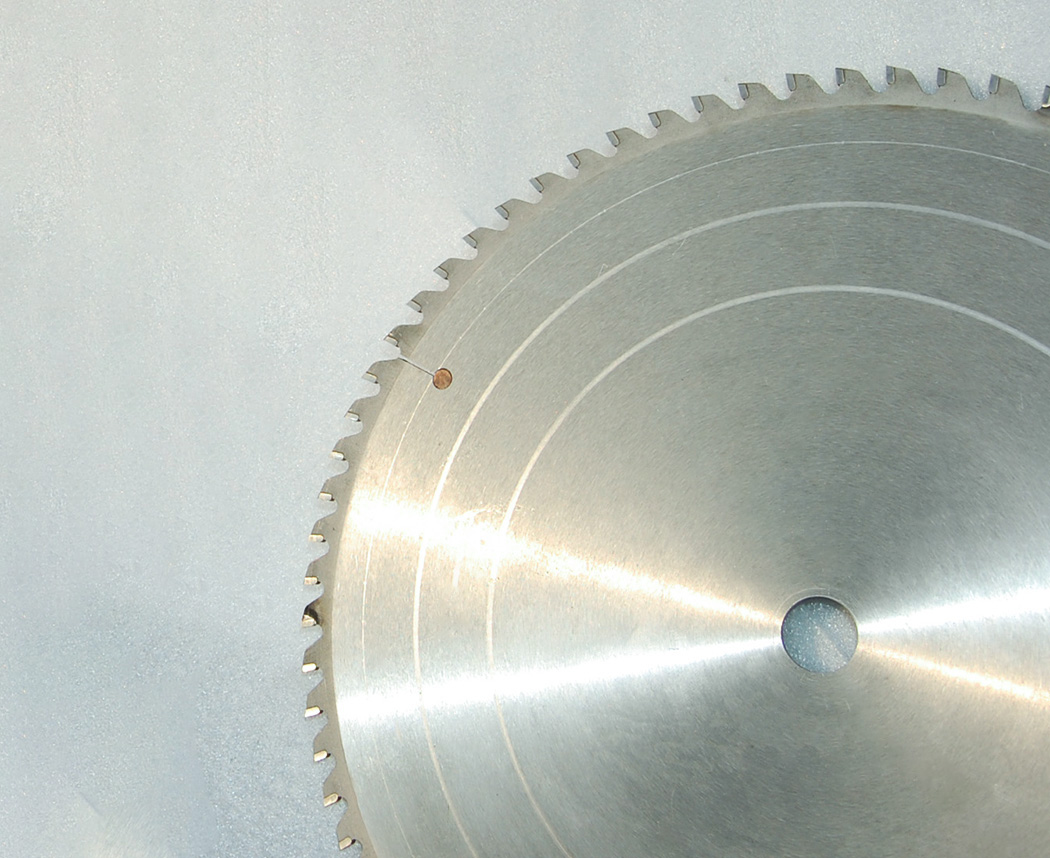

What are the applications of toothed saw blades in the wood processing industry

The toothed saw blade is a commonly used cutting tool in the wood processing industry, which significantly improves cutting efficiency and service life by embedding hard alloy teeth or other wear-resistant material teeth on the saw blade substrate. The following are its main application scenarios and characteristics in the wood processing industry:Sources:www.fhc018.com | PublishDate:2025.07.01

1、 Main application scenarios

1. Raw wood cutting and cutting

Application scenario: Used for cutting logs into boards, squares, or a certain length of wood, which is a key step in the initial processing of wood.

Features: The hard alloy teeth of the toothed saw blade have high hardness and strong impact resistance, which can effectively cut logs of different materials such as hardwood and wet wood, and the cutting surface is flat, reducing wood waste.

Typical equipment: band saw machine, circular saw machine (such as Longmen saw).

2. Sheet metal processing and forming

Furniture board cutting: In furniture manufacturing, large-sized boards (such as plywood, particleboard, and density board) are cut into standard sizes for cabinets, door panels, and other components, requiring high cutting accuracy and smooth edges.

Features: The saw blade tooth shape design (such as ladder flat teeth, left and right teeth) can reduce the edge breakage of the board, especially suitable for the processing of board after surface treatment such as veneer.

Solid wood panel processing: it is used to cut solid wood table boards, floor strips, etc., taking into account the cutting efficiency and wood texture protection to avoid cracking.

3. Production of solid wood flooring

Application scenario: When cutting solid wood plates into floor strips, the length, width and thickness should be controlled correctly, and the flatness of edge splicing should be ensured.

Features: The wear resistance of the inlaid saw blade can meet the requirements of mass production, and the edge of the floor strip after cutting is smooth, which is convenient for subsequent mortise tenon splicing or lock installation.

4. Processing of wooden pallets and packaging boxes

Application scenario: Cutting wood into pallet bottom plates, crossbeams, or packaging box side plates, bottom plates, etc. requires relatively low cutting accuracy, but requires efficient processing of large quantities of wood.

Features: The saw blade can adapt to thicker cutting needs, is wear-resistant, reduces replacement frequency, and lowers production costs.

5. Customized wood processing (such as wood carving, handicrafts)

Application scenario: Used for cutting complex shaped wood parts (such as wood carving blanks and craft frames), the saw blade needs to have flexibility and accuracy.

Features: Some toothed saw blades are designed with fine teeth or special tooth shapes, which can achieve curved cutting or processing and reduce wood damage.

2、 Advantages and selection points of toothed saw blades

1. Core advantages

Long service life: Hard alloy teeth have strong wear resistance, with a service life 3-5 times longer than ordinary steel saw blades, especially suitable for high load processing.

High cutting efficiency: Optimizing the tooth profile design (such as sawtooth angle and chip groove) can accelerate cutting speed, reduce wood heating and deformation.

Wide adaptability: It can cut wood of different hardness and moisture content, even waste wood containing a small amount of nails (requiring special wear-resistant teeth).

2. Key factors for selection

Wood type: Hardwood (such as oak and walnut) requires high hardness alloy teeth, while softwood (such as pine) can use medium hardness saw blades.

Cutting accuracy: Furniture board processing requires fine teeth (small tooth pitch), while raw wood cutting can use coarse teeth (large tooth pitch, fast chip removal).

Equipment matching: Select the appropriate diameter and aperture of the saw blade based on the saw power and speed (such as circular saw blades with a diameter of typically 150-600mm).

3、 Industry Trends and Technological Developments

Adaptation between intelligence and automation: With the increasing automation level of wood processing production lines, toothed saw blades are developing towards high precision and low vibration to meet the cutting needs of CNC equipment.

Environmental protection and energy conservation: New alloy materials and coating technologies (such as diamond coatings) can reduce cutting noise and dust, while also lowering energy consumption.

Customized services: For special woods (such as anti-corrosion wood and bamboo) or processing techniques (such as finger joint cutting), saw blade manufacturers can provide customized tooth profiles and material solutions.